🛠️ An AI designs an alloy 5 times stronger than traditional aluminum

Follow us on Google News (click on ☆)

To achieve this, these researchers have developed an original method for 3D printing aluminum alloys with remarkable performance. By integrating machine learning techniques, they have identified a specific formulation that produces parts much stronger than those obtained through conventional processes.

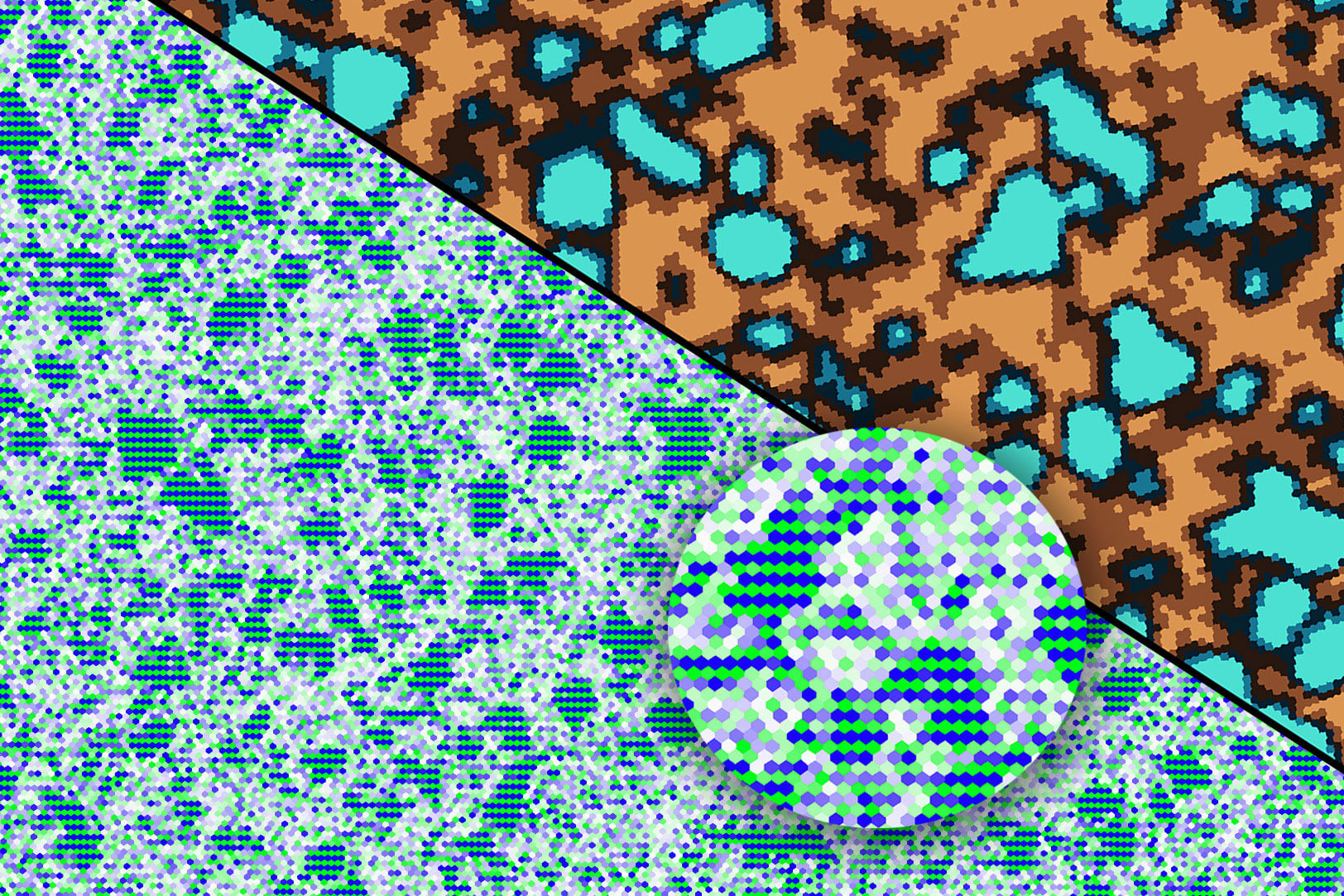

A new 3D-printed aluminum alloy is stronger than traditional aluminum, thanks to a recipe that produces aluminum (in brown) with nanoscale precipitates (in light blue). These precipitates arrange into regular patterns (blue and green in the inset) to confer exceptional strength.

Credit: Felice Frankel

This approach has greatly facilitated the search for the right composition. Rather than exploring millions of potential combinations, the simulations focused on about forty promising candidates. This efficient strategy led to the discovery of an alloy optimized for 3D printing, thereby avoiding tedious calculations.

3D printing, or additive manufacturing, plays a central role in this process. The laser powder bed fusion technique allows for rapid cooling, which promotes the formation of fine, dense microstructures. These characteristics are important for obtaining increased strength, as they prevent the growth of precipitates during solidification.

Tests performed on the printed samples confirmed the initial predictions. The alloy exhibits strength five times greater than that of traditionally cast aluminum. It also retains its stability at high temperatures, reaching up to 752 degrees Fahrenheit (400 degrees Celsius), which is notable for this type of material.

Potential applications span several fields, from fan blades in aircraft engines to cooling systems for data centers. This advance could enable lighter and more energy-efficient designs, with interesting implications for sectors such as transport or industry.

The scientific team now wishes to extend this approach to other alloys, opening new perspectives for the design of high-performance materials. According to experts cited in Advanced Materials, this methodology could change the way we produce complex metal parts in the future.

The efficiency of machine learning in materials science

Machine learning accelerates the discovery of new materials by rapidly analyzing vast datasets. Instead of testing every possible combination, algorithms identify patterns and correlations between the properties of elements. This approach reduces the time and resources required by targeting the most promising compositions for more in-depth simulations.

In the field of alloys, these tools can predict how the microstructure evolves based on the elements added. They help, for example, in understanding which ingredients promote the formation of nanoscale precipitates that strengthen the material. This avoids many fruitless experiments and guides researchers toward optimal solutions.

The mechanisms of rapid solidification in 3D printing

Rapid solidification is an important process in metal 3D printing, particularly with techniques like laser powder bed fusion. When molten metal cools quickly, it does not have time to form coarse structures, leading to finer and denser microstructures. These characteristics improve the mechanical strength of the final material.

In the case of aluminum, accelerated cooling prevents the growth of precipitates—tiny particles that form during solidification. By maintaining them at a nanoscale, they are distributed uniformly and strengthen the alloy instead of weakening it. This phenomenon explains why 3D printing can produce alloys stronger than those manufactured traditionally.