💪 These artificial tendons make robots 30 times stronger

Published by Cédric,

Article Author: Cédric DEPOND

Source: Advanced Science

Other Languages: FR, DE, ES, PT

Article Author: Cédric DEPOND

Source: Advanced Science

Other Languages: FR, DE, ES, PT

Follow us on Google News (click on ☆)

The heart of the innovation lies in the creation of artificial tendons. Designed as mechanical intermediaries between biological material and synthetic parts, these tendons are made from a special hydrogel. Together, the muscle and this hydrogel form a coherent functional unit. This architecture replicates the natural muscle-tendon-bone pattern, thus optimizing the transfer of contraction force to a robotic actuator, such as a gripper.

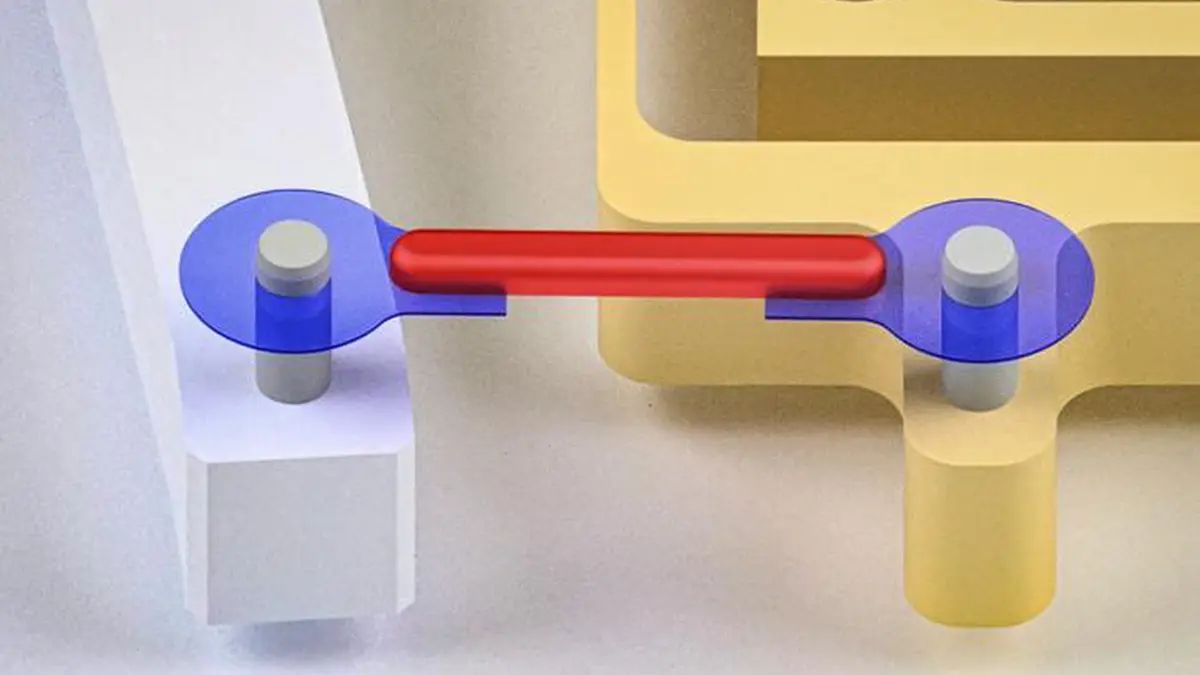

Researchers have developed artificial tendons for robots with artificial muscles. They attached these elastic tendons (in blue) to each end of a small fragment of lab-grown muscle (in red), thus forming a "muscle-tendon unit". (Credit: Ritu Raman et al.)

The biomechanical principle: an intelligent junction

The main difficulty with biohybrid robots came from the mechanical incompatibility between the high flexibility of muscle tissue and the rigidity of artificial skeletons. A direct attachment often led to muscle damage or energy loss. The MIT team solved this problem by drawing inspiration from nature, where tendons precisely serve as transition elements.

The researchers modeled the system as a set of three elements with distinct properties, representing the muscle, tendons, and robotic skeleton. This modeling made it possible to calculate the ideal stiffness of the artificial tendons to transmit maximum force without damaging the muscle. The chosen material, a hydrogel, was designed to possess exactly this property.

Once fabricated, these hydrogel cables were attached to the ends of a strip of muscle. The assembly was then connected to the fingers of a robotic gripper. This configuration concentrates the contraction force on the desired movement, thus avoiding the energy waste of previous designs.

Increased performance and new modularity

The results, published in the journal Advanced Science, are clear. Compared to a system where the muscle is attached directly to the skeleton, the device with artificial tendons allowed the gripper to close three times faster. Even more remarkably, the force exerted was increased by a factor of 30. This rise demonstrates the improvement in mechanical transfer.

The system's durability was also tested, with the muscle-tendon unit maintaining its performance over more than 7,000 contraction cycles. The researchers indicate that the system's power-to-weight ratio was multiplied by 11. A small amount of muscle tissue, properly connected, can therefore achieve a much more effective movement.

This breakthrough introduces a high degree of modularity into the design of biohybrid robots. As Ritu Raman points out, the artificial tendons act as interchangeable connectors. This approach makes it possible to assemble systems of different natures, whether micrometric (micrometer-scale) tools for surgery or autonomous devices, each time choosing the appropriate motor unit.