Replacing cement with bacteria for construction, it's possible!

Published by Cédric,

Article author: Cédric DEPOND

Source: Fraunhofer

Other Languages: FR, DE, ES, PT

Article author: Cédric DEPOND

Source: Fraunhofer

Other Languages: FR, DE, ES, PT

Follow us on Google News (click on ☆)

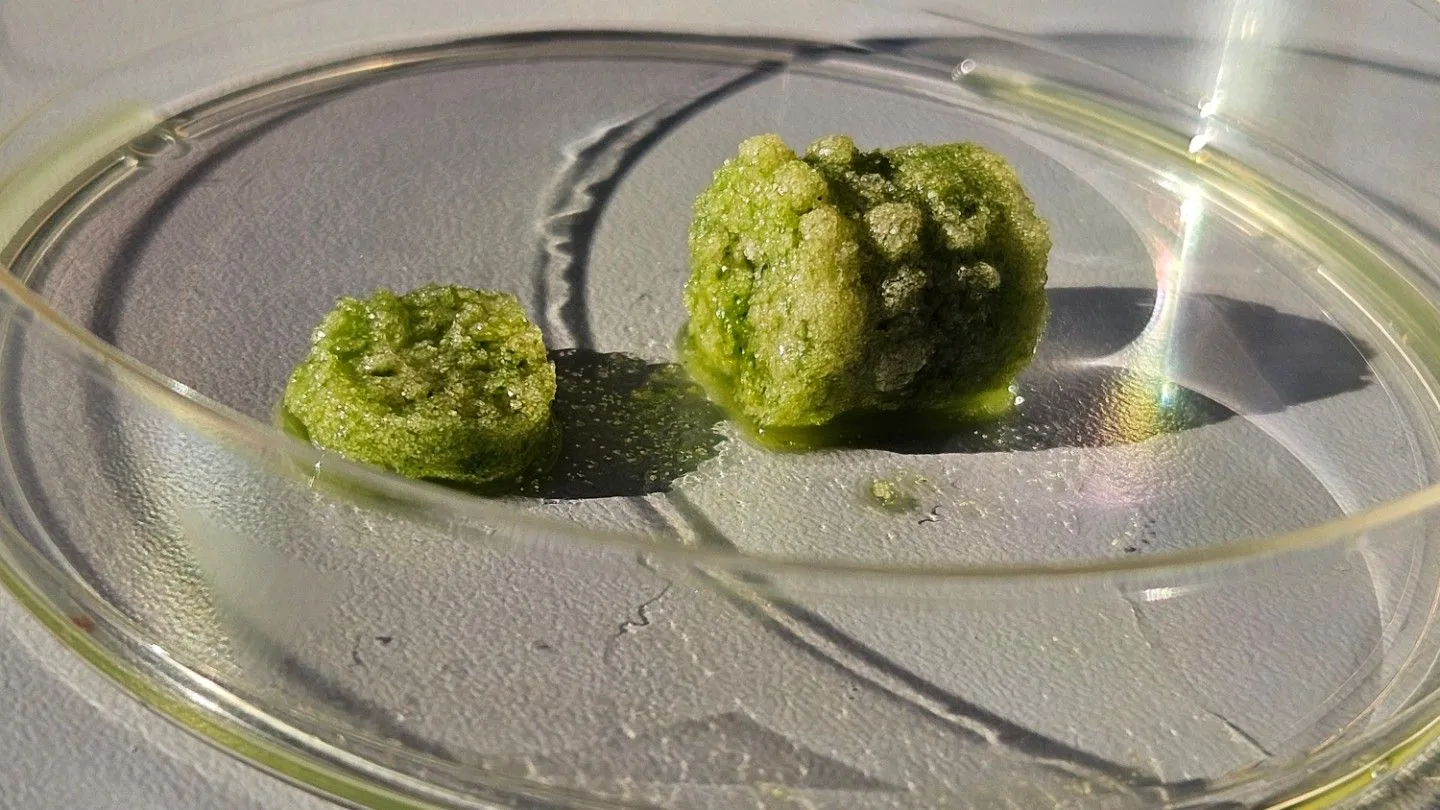

Living construction material (green color given by the chlorophyll of living bacteria).

© Fraunhofer IKTS

The construction industry faces a major challenge: cement, the primary component of widely used concrete, significantly contributes to climate change due to its high carbon dioxide emissions. In 2018, cement production in Germany generated approximately 20 million metric tons (22 million US tons) of CO2, accounting for nearly 10% of national industrial emissions according to the German Environment Agency (UBA).

To address this environmental issue, researchers from the Fraunhofer Institutes for Ceramic Technologies and Systems (IKTS) and for Electron Beam and Plasma Technology (FEP) have developed the "BioCarboBeton" project. This project introduces a biological production method that not only eliminates carbon emissions but also utilizes atmospheric CO2 in the manufacturing process.

At the heart of this method are cyanobacteria, which are capable of photosynthesis. Under the combined action of light, moisture, and temperature, these microorganisms form structures similar to stromatolites, primarily composed of limestone. These biogenic structures have existed in nature for 3.5 billion years, underscoring the robustness and durability of this biological process.

Researchers have successfully replicated this natural process through an advanced technological approach. Dr. Matthias Ahlhelm from IKTS oversees the development of materials and processes, as well as the selection of filler and binding agents. Simultaneously, Dr. Ulla König's team at FEP is responsible for culturing the cyanobacteria, microbiological analysis, and scaling up biomass production.

Production begins with the cultivation of photosensitive cyanobacteria in a nutrient solution. Subsequently, to enable mineralization and the formation of stromatolitic structures, calcium sources such as calcium chloride are added to the bacterial solution. A mixture of hydrogels and various filler agents, like different types of sand, is prepared, while additional CO2 is incorporated to support the process.

The bacterial mixture is then homogenized and structured by being poured into translucent molds, thus allowing metabolic and photosynthetic processes to continue. Further mineralization leads to the final solidification of the material. Alternatively, porous substrates can be produced and treated with the cyanobacteria culture, offering flexibility in potential applications such as insulation, bricks, formwork fillings, and even mortar or stucco.

The BioCarboBeton project aims to determine the material and mechanical properties of the biogenic products, as well as to scale up production. Currently working with biogas and other calcium sources like basalt and mining residues, researchers are also exploring circular processes for sustainable and efficient production.

Having established and tested the process, the Fraunhofer research team is now working to increase production volumes and define the solid properties necessary for large-scale manufacturing of these eco-friendly materials. Drs. Ahlhelm and König are confident that their method paves the way for a promising biological technology for a circular economy, not only in the construction sector but also beyond.