This 3D printer fits in your hand!

Published by Cédric,

Author of the article: Cédric DEPOND

Source: Nature Light Science & Applications

Other Languages: FR, DE, ES, PT

Author of the article: Cédric DEPOND

Source: Nature Light Science & Applications

Other Languages: FR, DE, ES, PT

Follow us on Google News (click on ☆)

This tiny device could allow a user to quickly create customized and inexpensive objects on the go, such as a clip to fix a wobbly bike wheel or a component for a medical operation.

Credits: Sampson Wilcox, RLE

The demonstration device consists of a single millimeter-scale photonic chip emitting reconfigurable light beams into a liquid resin.

This resin hardens instantly when exposed to visible light emitted by the chip. Unlike traditional 3D printers, the prototype has no moving parts. It relies on a network of tiny optical antennas to precisely direct the light beam.

By combining silicon photonics and photochemistry, the research team has succeeded in printing arbitrary two-dimensional patterns, such as the letters "MIT," in just a few seconds. Jelena Notaros, a professor at MIT and the study's lead author, describes this technology as a reinvention of the 3D printer: "This system completely rethinks what a 3D printer is. It's no longer a big box sitting on a bench in a lab creating objects, but something portable. It's exciting to think of the new applications that could come out of this and how the field of 3D printing could change".

The researchers ultimately envision a system where a photonic chip placed at the bottom of a resin well would emit a 3D hologram of visible light, allowing an entire object to harden in a single step. Such a portable 3D printer could revolutionize many fields, particularly medical, by enabling the creation of custom components directly on-site.

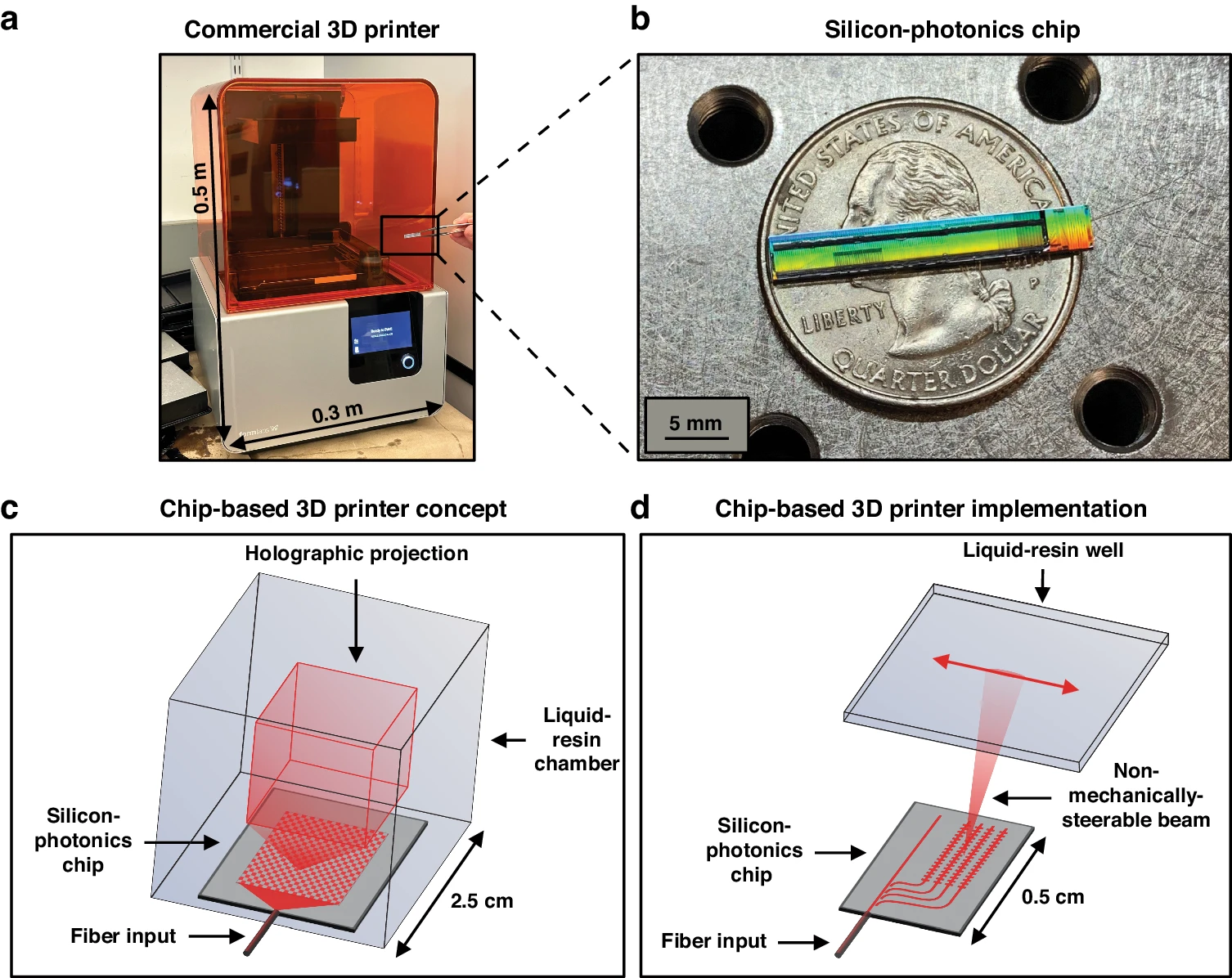

(a) Typical commercial 3D printer with a photonic chip (black framed) for comparison and (b) a fabricated and packaged photonic chip.

(c) Conceptual diagram of the proposed chip-based 3D printer, showing a hologram formed by a chip in a resin chamber (not to scale).

(d) Conceptual diagram of the chip-based 3D printer inspired by stereolithography demonstrated in this work (not to scale)

The prototype relies on a 160-nanometer-thick photonic chip (for comparison, a sheet of paper is 100,000 nanometers thick). Powered by an external laser, the chip emits a light beam into a photopolymerizable resin, hardening where the beam strikes. To control this beam, the researchers use compact liquid crystal modulators, integrated into the chip and adjusted via an electric field.

The close collaboration between Notaros' group at MIT, specialized in silicon photonics, and Page's group at the University of Texas at Austin, experts in photopolymerizable resins, has been essential. Together, they have fine-tuned chemical formulations to achieve a long-lasting and rapidly hardening resin.

Sabrina Corsetti, a graduate student in electrical and computer engineering, explains: "Here, we find ourselves halfway between standard photochemistry and silicon photonics by using visible light-curing resins and visible light-emitting chips to create this chip-based 3D printer. It's a fusion of two technologies into a completely new idea".

The application prospects for this technology are vast. In addition to medical uses and rapid prototyping, the team aims to develop a chip capable of generating 3D holograms, thus improving the efficiency of 3D printing.