Follow us on Google News (click on ☆)

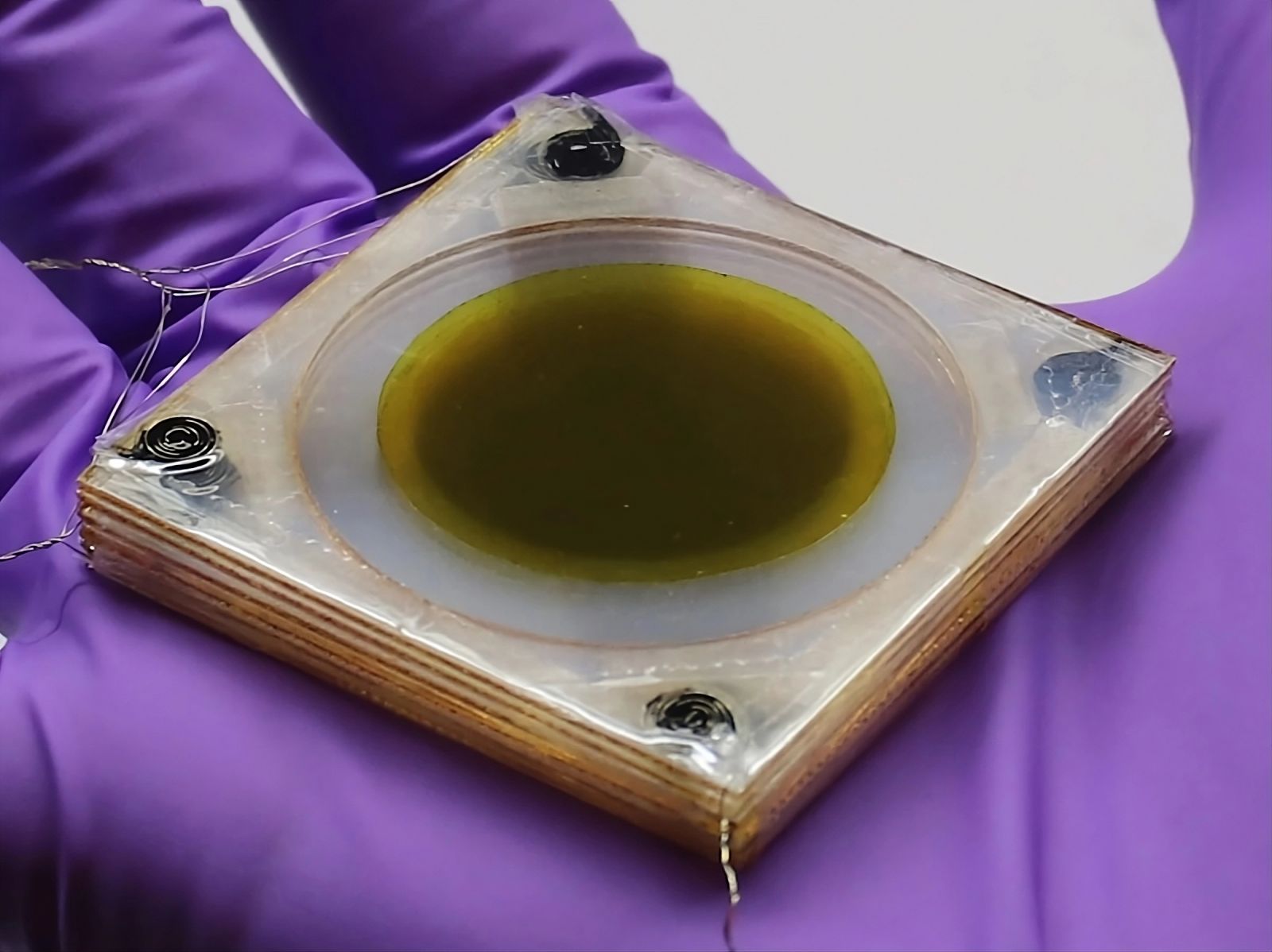

A new cooling device developed by UCLA consists of six thin layers of polymer films coated with nanotubes.

Credit: UCLA Soft Materials Research Laboratory

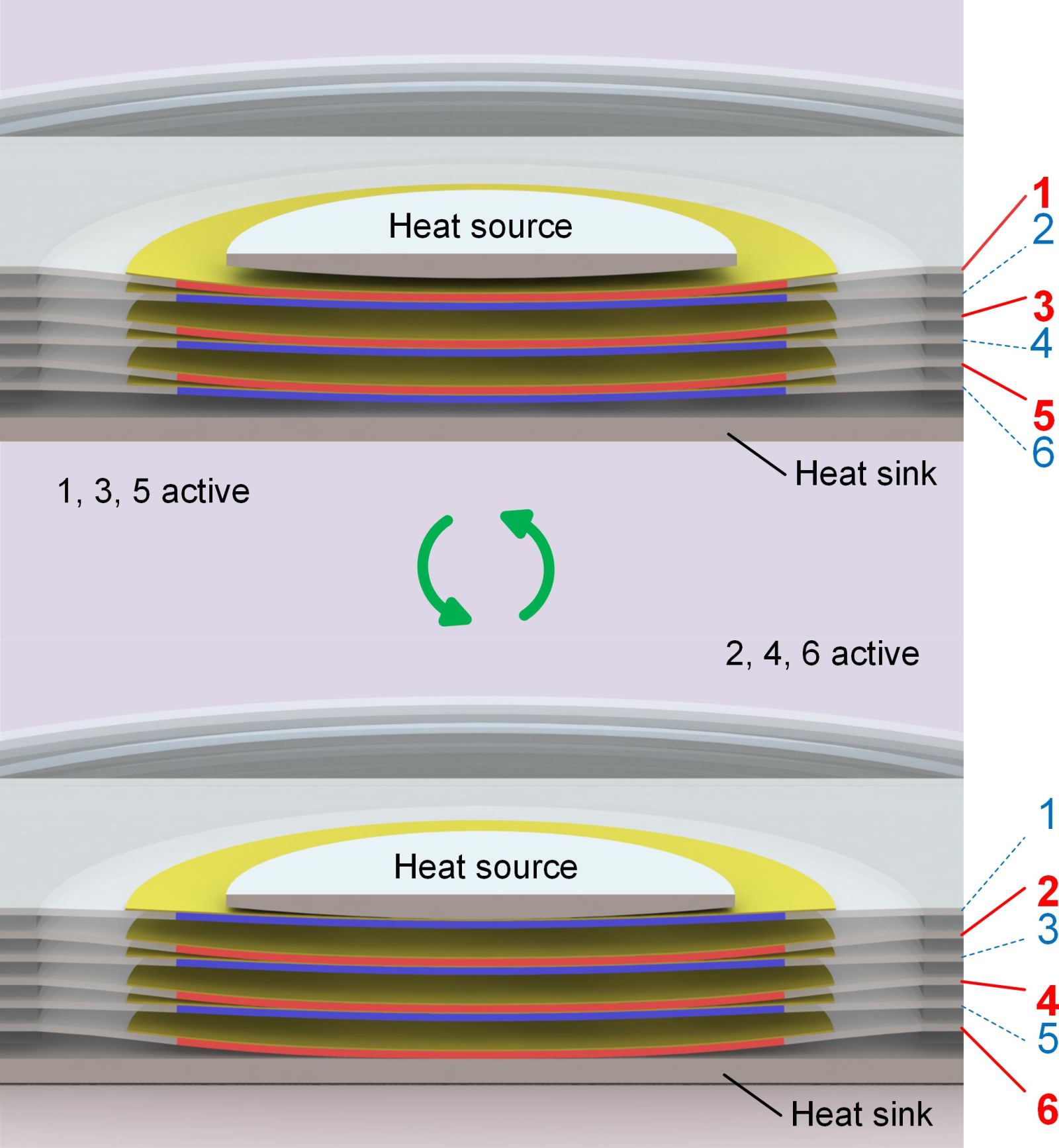

The core of this technology relies on ferroelectric polymer films that, under the influence of an electric field, change both temperature (electrocaloric effect) and shape (electrostriction). This process, alternating compression and expansion, enables continuous heat pumping. Unlike traditional air conditioning systems, this device does not require refrigerants, thereby reducing its environmental impact.

The research team, led by Qibing Pei, a materials science professor at UCLA, designed a cascade of polymer films to maximize thermal transfer efficiency. This architecture allows for a temperature differential of 25 °F (14 °C).

The research team envisions various applications for this technology, particularly in the field of portable cooling accessories. These devices could offer an energy-efficient solution for workers exposed to high temperatures.

The advantages of this device include its simplicity, energy efficiency, and potential for integration into portable systems. Researchers emphasize the importance of developing alternative cooling technologies in the face of rising global temperatures.

The device has been tested in the laboratory, demonstrating its ability to maintain continuous cooling. The results of these experiments have been published in the journal Science, marking a significant step toward practical applications.

The polymer films in the device expand and contract like an accordion to pump heat from a source, thereby cooling it.

Credit: UCLA Soft Materials Research Laboratory

In addition to its potential applications in portable technologies, this device could also be used to cool flexible electronic components. Researchers are currently working on optimizing this technology for large-scale use.

What is the electrocaloric effect?

The electrocaloric effect is a physical phenomenon where a material changes temperature in response to an applied electric field. This change is due to the reorientation of electric dipoles within the material, which alters its entropy and, consequently, its temperature.

In the context of cooling devices, the electrocaloric effect allows for pumping heat from one area to another without using refrigerants. This makes cooling systems more environmentally friendly and potentially more efficient.

Electrocaloric materials are particularly promising for portable applications due to their flexibility and low energy consumption.

Research on the electrocaloric effect opens new avenues for the development of alternative cooling technologies, essential in the context of global warming.

How do ferroelectric polymers work in this device?

Ferroelectric polymers are materials that change temperature and shape under the influence of an electric field. In the UCLA cooling device, these polymers are arranged in thin layers, each coated with carbon nanotubes to enhance their electrical conductivity.

When an electric field is applied, the polymer layers compress (electrostriction) and release heat (electrocaloric effect). When the electric field is removed, the layers relax and absorb heat from the environment. This cycle of compression and expansion enables continuous heat transfer.

This mechanism of action, similar to that of an accordion, is both simple and effective. It allows the device to function without complex moving parts, thereby reducing the risk of failure and maintenance needs.

The use of ferroelectric polymers in cooling devices represents a significant advancement in the field of smart materials, offering innovative solutions for thermal management.