Follow us on Google News (click on ☆)

Researchers from the Laboratory of Nanotechnology and Nanosystems, University of Sherbrooke, National Institute of Scientific Research, and Materials Engineering and Science Laboratory, united within an International Research Laboratory (IRL), have developed a new silicon anode architecture.

According to studies published in the journal Energy Storage Materials, these anodes store at least three times more energy than expected, and over two hundred cycles instead of just a few.

With the increasing demand for high-energy-density batteries in portable electronic devices, the Internet of Things, and electric vehicles, the maturity of lithium-ion battery technology, which relies on graphite anodes, is no longer sufficient. Silicon anodes, on the other hand, offer ten times the energy storage capacity by volume, but swell so much during charging that they degrade the battery after only a few cycles.

Thanks to a solid Franco-Québécois collaboration, researchers from the Laboratory of Nanotechnology and Nanosystems (LN2, CNRS/Centrale Lyon/INSA Lyon/Univ. Grenoble Alpes/Univ. Sherbrooke), University of Sherbrooke (University of Sherbrooke, Canada), National Institute of Scientific Research (INRS, Canada), and the Materials Engineering and Science Laboratory (MatéiS, CNRS/INSA Lyon/Univ. Claude Bernard) have developed a new silicon anode architecture that achieves state-of-the-art storage without damage for at least two hundred charge and discharge cycles.

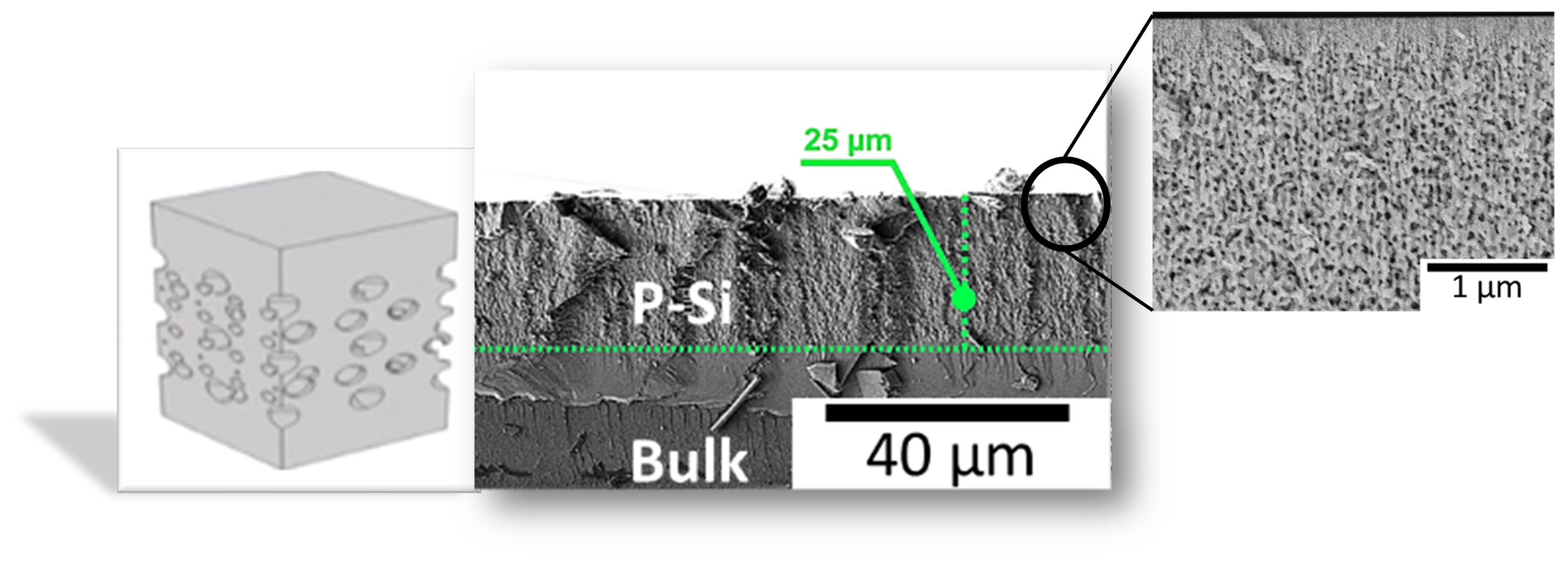

The researchers tackled the swelling problem by using porous silicon. The volume increase during charging occurs inward, reducing the size of the pores, instead of swelling the entire material. However, this structure leads to the irreversible accumulation of lithium in the pores, affecting battery performance. The researchers then applied a heat treatment that forms a tiny surface layer of solid silicon, reducing the contact surface with the electrolyte.

Detail of a silicon anode with the porous layer (P-SI) and the solid layer (Bulk).

© Sofiane Abdelouhab et al.

This architecture also showcases unique, albeit poorly understood, mechanical properties. The sandwich structure displays storage performance of 9 mAh.cm-2 over more than two hundred cycles, which is three times the threshold considered significant by industry. In a limited number of cycles, these anodes even reach up to 20 mAh.cm-2. All these advancements have been achieved using low-cost methods, compatible with conventional microelectronics processes.

This process has been patented, and the team is now exploring how to operate these anodes with solid electrolytes, which are safer than their liquid counterparts.

References:

High-areal capacity Si architecture as an on-chip anode for lithium-ion batteries.

Sofiane Abdelouhab, Graniel Harne A. Abrenica, Alexandre Heitz, Sylvain Meille, Lionel Roué, Abderraouf Boucherif, Denis Machon.

Energy Storage Materials, Volume 65, 2024.

https://doi.org/10.1016/j.ensm.2023.103172