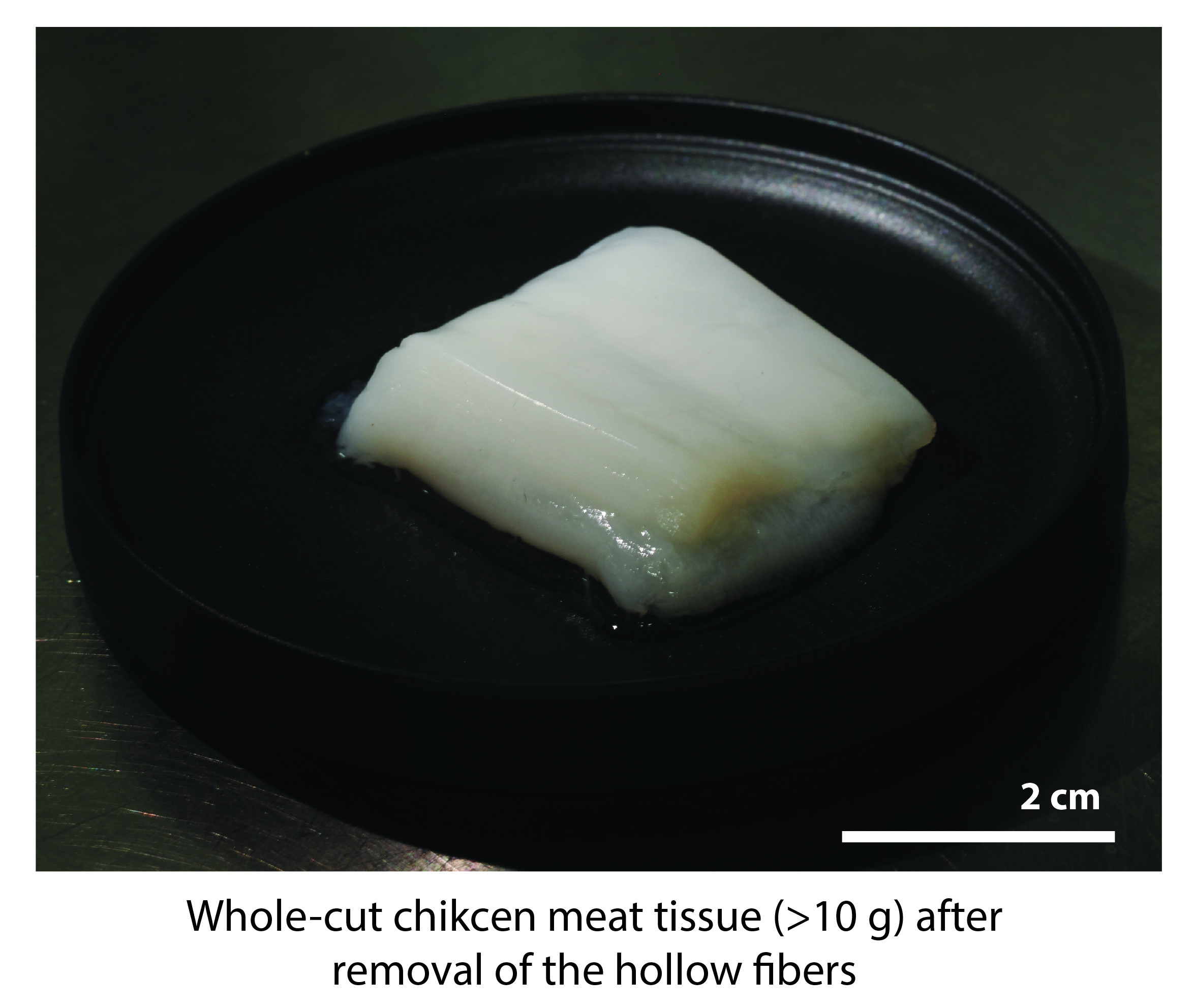

Here are 10 grams of chicken meat... grown in a lab 🍗

Follow us on Google News (click on ☆)

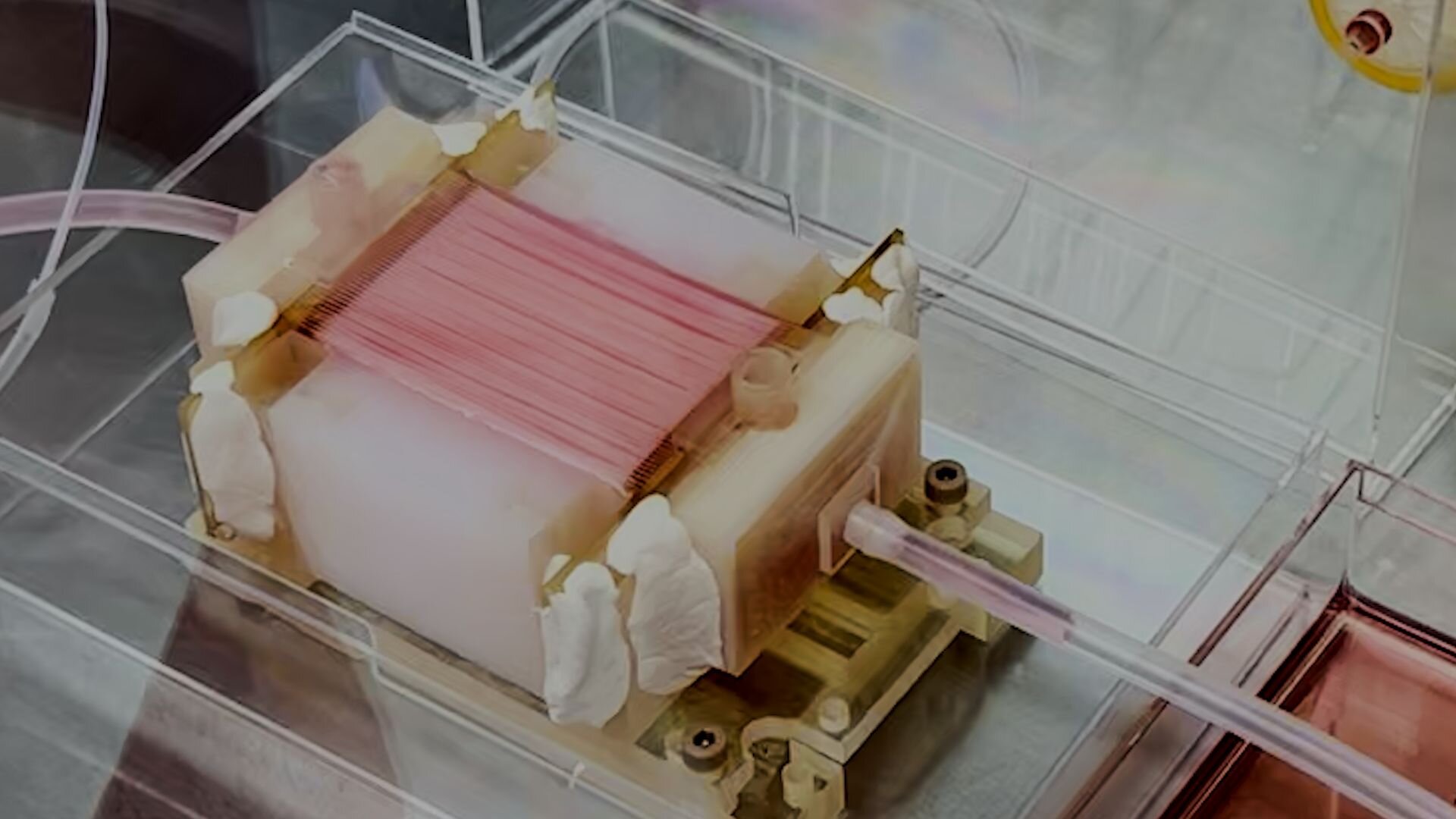

Chicken produced using a bioreactor with 1,125 fibers.

Credit: Shoji Takeuchi, The University of Tokyo

Shoji Takeuchi's team at the University of Tokyo has developed a bioreactor that uses hollow fibers to nourish muscle cells. These fibers, similar to those used in dialysis, enable optimal nutrient distribution. Their study, published in Trends in Biotechnology, opens new possibilities for cultured meat and regenerative medicine.

The system overcomes a major limitation: nutrient diffusion in thick tissues. The precisely arranged hollow fibers simulate blood vessels. This method has allowed the creation of muscle tissue several centimeters thick—a first in the field of cultured meat.

The technology uses chicken fibroblasts to structure the meat, improving its texture and taste. Takeuchi highlights its potential for sustainable and ethical production. Applications could extend to organ fabrication and biohybrid robots.

Remaining challenges include improving oxygen delivery and using edible materials. Takeuchi envisions artificial oxygen carriers to mimic red blood cells. Automating fiber removal and recycling is also under study.

Perfusion in the bioreactor.

Credit: Shoji Takeuchi, The University of Tokyo

This research marks a key step toward large-scale cultured meat production. It demonstrates the efficiency of hollow-fiber bioreactors for biofabrication. The implications go beyond food, extending to medicine and robotics.

The team is now working to optimize the mechanical properties of the tissues. The goal is to better mimic the characteristics of natural muscles. This breakthrough could revolutionize meat production and regenerative therapies.

How does a hollow-fiber bioreactor work?

A hollow-fiber bioreactor uses microscopic tubes to distribute nutrients and oxygen to cells. These fibers mimic blood vessels, enabling efficient perfusion throughout tissues.

This technology is inspired by medical devices like dialysis machines. The fibers are semi-permeable, allowing necessary substances to pass while maintaining tissue structure.

Precise fiber arrangement is crucial to ensure even distribution. This enables the nourishment of thick cell layers, which would be impossible to sustain through simple diffusion.

Applications range from cultured meat to organ fabrication. This approach could solve vascularization issues in grafts and tissue cultures.

What are the benefits of cultured meat?

Cultured meat offers a sustainable alternative to traditional livestock farming. It reduces environmental impact by limiting land and water use.

This method also avoids ethical concerns related to animal slaughter. Cells are harvested without harming the animal and then grown in a lab.

Cultured meat can be designed to enhance its nutritional quality. Lipid profiles can be adjusted, or it can be enriched with vitamins.