Follow us on Google News (click on ☆)

Researchers from the University Institute of Industrial Thermal Systems and Chryso France have discovered that the stresses actually focus on a short section of the pipe, allowing the other parts of the flow to remain fluid. Published in the journal PNAS, this research is of interest for the numerous industrial applications of shear-thickening fluids.

Composed of particles about ten microns (0.0004 inches) in suspension, shear-thickening fluids flow like conventional viscous liquids under low stress but solidify when vigorously sheared. This behavior arises from the repulsion between particles, which slide under low stress and rub against each other under high stress. This is why you can sink into a pool of water mixed with cornstarch if you enter it gently, but not if you run quickly enough.

These materials, such as high-performance concrete before setting, chocolate paste, or certain magmas, still manage to circulate in pipes despite the pressure that should solidify them. Indeed, the flow rate stops increasing proportionally to the stress when it exceeds the level that should theoretically solidify the material, but the flow persists without fluctuations in the flow rate.

Researchers from the University Institute of Industrial Thermal Systems (IUSTI, CNRS/Aix-Marseille University) and the company Chryso France have revealed and explained the mechanism behind this peculiar flow: the stresses concentrate on a short section of the pipe, allowing the rest of the flow to remain fluid. This plug-like zone, as short as the diameter of the pipe, allows the flow to pass while moving upstream.

Since shear-thickening fluids are dense suspensions, they are not transparent. The researchers could only observe the flow in the hundred microns (0.004 inches) closest to the pipe wall. They added fluorescent tracers, which provided them with the velocity gradients of the flow along the wall and towards the center of the pipe.

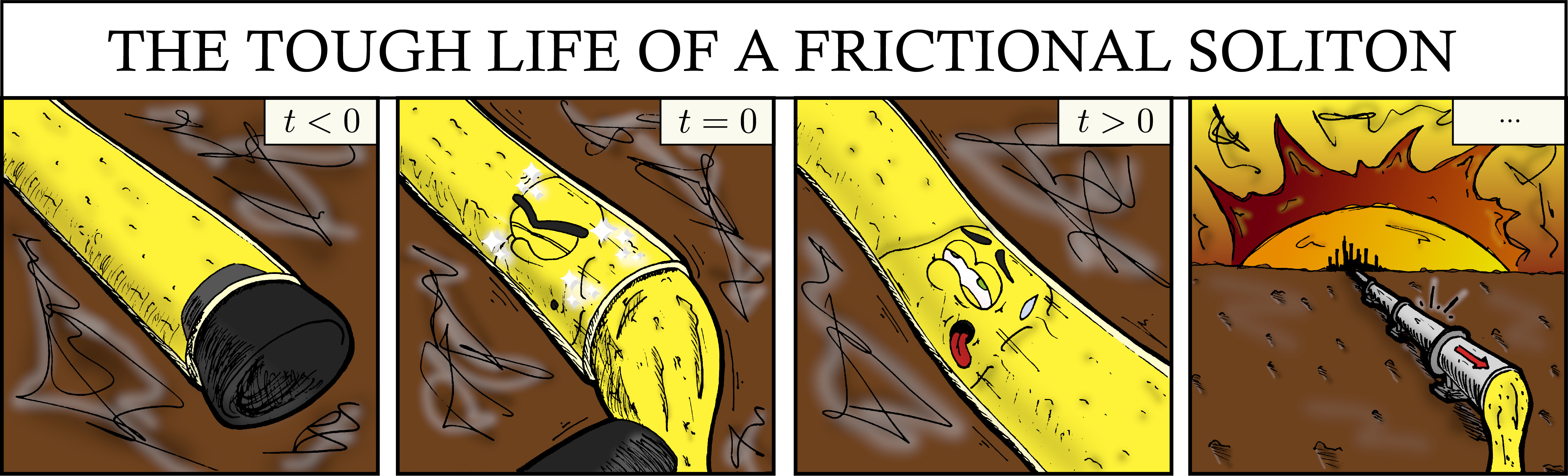

They identified the plug-like zone, called a frictional soliton, because the grains rub against each other and it moves upstream like an isolated wave. The soliton extends continuously upstream while disintegrating downstream. There is only one soliton at a time in the pipe, and it only appears when the pressure raises the stresses above the solidification threshold. Once the soliton reaches the top of the pipe, it disappears and reforms immediately at the bottom to start its ascent again.

The soliton forms at the end of the pipe as soon as the valve is opened. It moves upstream, extending as quickly upstream as it disintegrates downstream, never blocking the flow.

© A. Bougouin

Pressure measurements along the pipe confirm that the pressure drop concentrates in the section where the soliton is located, allowing the other sections to remain fluid. This behavior has been verified for several suspensions composed of grains with varying compositions, shapes, and sizes.

This research could help establish flow laws for many industrial applications, such as in construction or food processing. For this, it remains to understand what happens when the flow also passes through bends and reservoirs.

References:

A frictional soliton controls the resistance law of shear-thickening suspensions in pipes.

Alexis Bougouin, Bloen Metzger, Yoël Forterre, Pascal Boustingorry & Henri Lhuissier.

PNAS, 2024.

https://doi.org/10.1073/pnas.2321581121