Follow us on Google News (click on ☆)

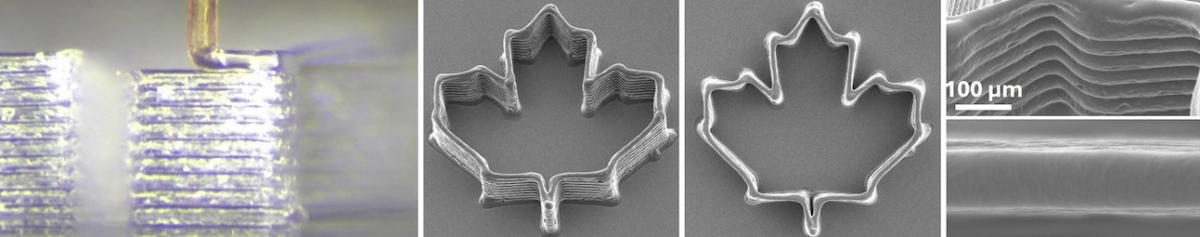

Thanks to the unique geometric, structural, and mechanical characteristics of the proboscis, lines with a width of 20 microns can be printed, which is slightly smaller than a white blood cell and about twice as fine as what currently available commercial printing nozzles can produce.

Illustration image Pixabay

The researchers have named this process "3D necroprinting," in which a non-living biological microstructure is used directly as a 3D printing tool. Among the potential applications are the production of tiny scaffolds for cell growth or tissue engineering, printing of cell-laden gels, and the transfer of microscopic objects such as semiconductor chips.

"For high-resolution 3D printing and microdispensing, ultra-fine nozzles are needed, typically made from metal or specialized glass," explains Jianyu Li, co-author of the study, associate professor at McGill University and holder of the Canada Research Chair in Tissue Repair and Regeneration. "These nozzles are expensive and difficult to manufacture, pose health risks, and generate waste."

"Mosquito proboscises allow us to print extremely small and precise structures that are difficult or very costly to produce with conventional tools. Since the biological nozzles are biodegradable, we can reuse materials that would otherwise be discarded," adds Changhong Cao, co-author of the study, assistant professor at McGill University and holder of the Canada Research Chair in Advanced Small-scale Materials and Manufacturing in the Department of Mechanical Engineering.

The study was led by Justin Puma, a graduate student at McGill University. Justin had previously participated in a study on the use of a mosquito proboscis for biomimetic purposes, which laid the groundwork for this research.

Biodegradable and reusable

To develop the nozzles, the team examined micro-nozzles made from insects and determined that the mosquito proboscis—a tiny micro-needle with a width equivalent to about half a human hair—was the best choice. The proboscises were harvested from euthanized mosquitoes from ethically approved laboratory colonies used for biological research at Drexel University, a partner institution.

Under a microscope, the researchers carefully removed the mosquito's feeding tube. They then attached this biological needle to the tip of a standard plastic dispenser using a small amount of resin. They characterized the geometry and mechanical strength of the tips and measured their pressure tolerance, then integrated the tips into a custom 3D printing device.

Once connected, the proboscis becomes the orifice through which the 3D printer extrudes the material. The researchers successfully printed complex high-resolution structures, including a honeycomb structure, a maple leaf, and bio-scaffolds containing cancer cells and red blood cells.

The idea of using biotic materials in advanced manufacturing was inspired by necrobotics research conducted at Rice University. While conducting research on micro-nozzles, Cao was also discussing another mosquito-related project with Megan Creighton and Ali Afify, researchers at Drexel University. These conversations led the team to explore proboscises for 3D printing.

"Advances in the field of bioprinting are helping medical researchers develop unique therapeutic approaches. While seeking to improve the technology, we must also strive to innovate," said Megan Creighton, co-author of the study and assistant professor of chemical and biological engineering.

"We discovered that the mosquito proboscis could withstand repeated printing cycles as long as the pressures remained within safe limits. Handled and cleaned properly, a nozzle can be reused multiple times," specifies Professor Cao.

"By using biotic materials as viable substitutes for complex technical components, this work paves the way for sustainable and innovative solutions in the field of advanced manufacturing and micro-engineering," concludes Professor Li.

The study

The paper "3D Necroprinting: Leveraging biotic material as the nozzle for 3D printing," by Justin Puma, Megan Creighton, Ali Afify, Jianyu Li, Changhong Cao et al., was published in Science Advances.

The research was funded by the New Frontiers in Research Fund – Exploration Stream, the Natural Sciences and Engineering Research Council of Canada (NSERC) Discovery Grants Program, the Fonds de recherche du Québec – Nature et technologies (FRQNT) Support for Research for New Professors Program, the John R. Evans Leaders Fund of the Canada Foundation for Innovation, the Canada Research Chairs Program, and an NOVA grant – FRQNT-NSERC.