Follow us on Google News (click on ☆)

Cheese production consists of concentrating the proteins and fats in milk by removing the aqueous portion, called "whey." This process relies on the enzymatic gelation of milk and the destabilization of "casein micelles," natural colloids that concentrate most of the milk's proteins.

After formation, enzymatic milk gels undergo a spontaneous maturation process, called aging, during which their mechanical properties strengthen over time. This reinforcement allows the gels to be cut into small pieces and initiates syneresis, the contraction of the protein network and the expulsion of whey.

During aging, the moment when cutting begins is crucial, not only for controlling the water content of the cheese but also for improving production yields and minimizing protein and fat loss in the whey. Nevertheless, current production processes remain largely empirical, as the mechanisms governing gel formation and aging are not fully understood.

In a recent study, researchers from the Laboratoire de Physique at the ENS de Lyon (LPENSL, CNRS / ENS de Lyon) leveraged the emergence of time-resolved mechanical spectroscopy, a new technique allowing for a complete and rapid characterization of the rheological properties of materials.

By coupling these rheometric measurements with structural characterizations, they showed for the first time that the microscopic scenario governing the macroscopic dynamics of enzymatic milk gels involves two sequential steps. First, the particulate network formed at the gelation threshold compacts, leading to a rapid increase in the "firmness" or "elasticity" of the gels. Second, the microstructure of the gel solidifies, and further aging occurs through the evolution of the contacts between the particles forming the gel.

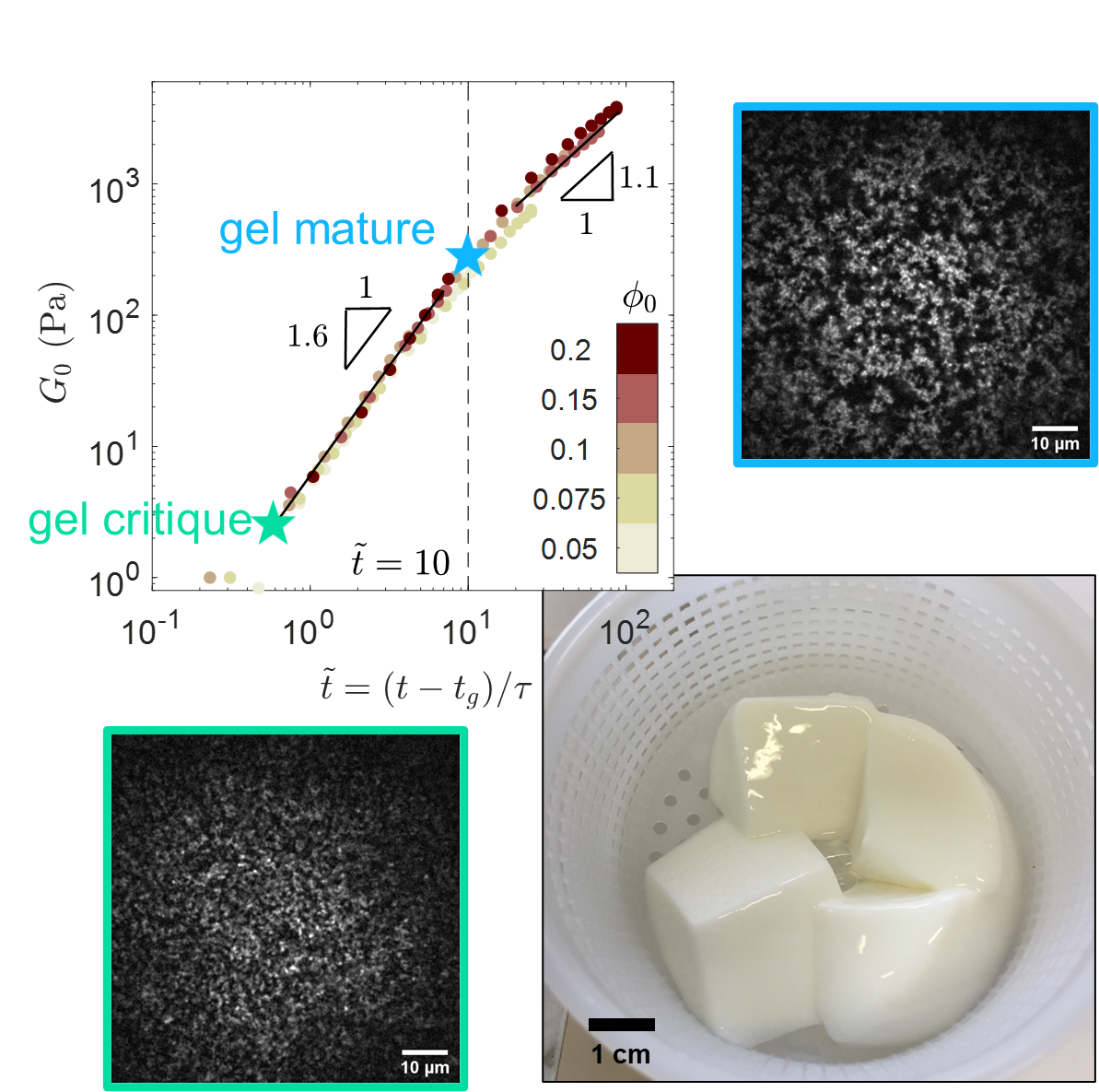

Characteristic elasticity (G0) of enzymatic milk gels during aging and at different volume fractions (Φ0).

Shown as a function of a dimensionless time (t) accounting for the gelation time, the elasticity evolution reveals two distinct regimes, separated by a critical time (~20').

Microscopy images show the compaction of the particulate network coinciding with the increase in gel elasticity. An image of gel pieces immediately after cutting is also depicted.

© T. Gibaud.

Identifying these two aging regimes, separated by a critical time (around twenty minutes), is a promising discovery for the cheese industry. Through pilot trials, the challenge now is to translate this knowledge into manufacturing practices that aim to optimize and automate the early stages of cheese production. Furthermore, this study reaches far beyond food sciences.

For the first time, these results demonstrate the macroscopic signature of the aging of a colloidal gel induced by the evolution of contacts at the particle level. The original aging scenario of enzymatic milk gels contrasts with other colloidal gels made of hard particles, in which the global network structure remains constant throughout aging.

This highlights the added complexity of these biological systems composed of soft particles, and calls for new theoretical frameworks to describe them. These results are published in the journal Physical Review Materials.

Reference:

Two-step aging dynamics in enzymatic milk gels,

Physical Review Materials, published July 9, 2024.

Doi: 10.1103/PhysRevMaterials.8.L072601

Open archive: arXiv