Follow us on Google News (click on ☆)

Developed by Airbus Defence and Space on behalf of the ESA and operated by the CADMOS, a center dedicated to microgravity activities of the French National Centre for Space Studies (CNES), the Metal 3D printer is a pioneering experiment on the ISS.

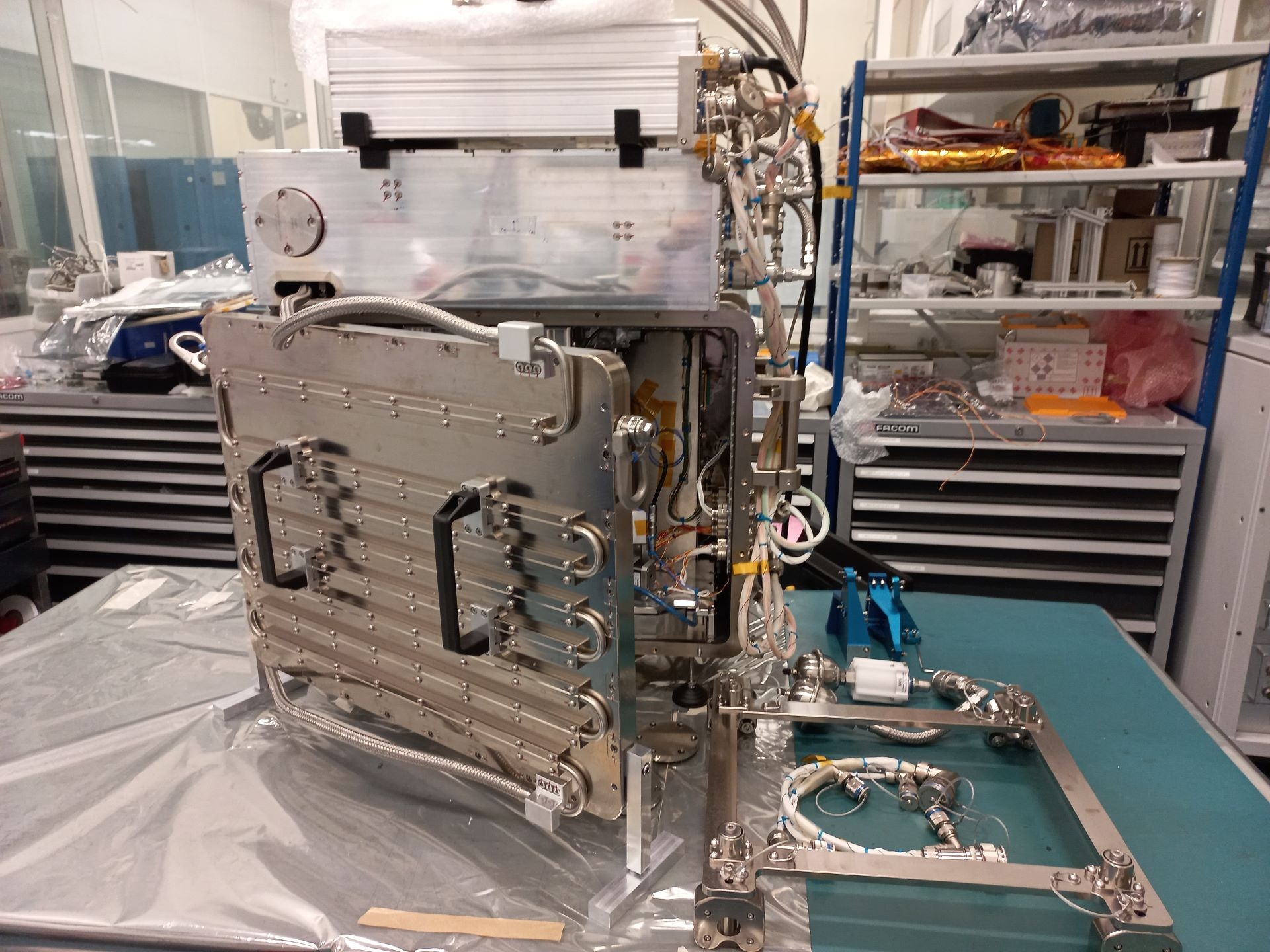

Flight model of the Metal 3D printer.

Credits: © ESA

How does it work?

First, the stainless steel wire is fed into the print area. The printer then melts it using a laser, a million times more powerful than a standard laser pointer. The printer successively adds the molten metal to the print.

The ISS has quite stringent safety standards... And fortunately for our astronauts! With the metal's melting point around 2552°F (1400°C), the Metal 3D printer is placed in a completely sealed box. Before starting, the box's oxygen is entirely replaced by nitrogen, which is far less flammable. This also prevents the metal from oxidizing on contact with oxygen.

Metal 3D Printer in operation.

© Airbus Defence and Space SAS

02/12: the setup

The Metal 3D printer was installed in the Columbus module of the ISS, more precisely in the EDR-2 (European Drawer Rack 2). As its name implies, it's a 3D printer designed to create metal parts by laying down successive layers. Given that merging metal as on Earth is impossible in the ISS, this printer operates using the same process as those using plastic: with a filament.

ESA astronaut Andreas Mogensen was tasked with installing it in the rack. The printer weighs around 396 lbs (180 kg): hard to handle on Earth, but it's truly child's play for Andreas Mogensen in the ISS.

03/11: starting the prints

A total of 4 print tests are planned, to recreate parts already printed on Earth. The printer is expected to create 4 parts, each weighing about 4.4 oz (125g), with each print taking about 4 weeks (operating 3 hours and 30 minutes per day). The goal is to demonstrate that it is possible to manufacture metal parts directly in space.

The purpose of this 3D printer would be to allow astronauts to be autonomous in the design and production of small metal parts, for example, for minor repairs. Its twin sister is present at CADMOS: a dedicated team will thus study the feasibility of such a challenge and will be able to compare the parts made with Earth's gravity and those made in the ISS, in microgravity.