Follow us on Google News (click on ☆)

A blend of chemical engineering and mechanical engineering catalyzes the development of an inspiring green solution, transitioning from the beaker stage to university-scale implementation and ultimately aiming for global change. The concept of using greenhouse gases as raw materials is certainly appealing!

The idea of creating green fuels using these gases as a carbon source isn't new. However, one major issue with various initiatives to produce green fuels is the prohibitively high costs.

"Several factors contribute to these high costs, including an overly complex purification process and expensive equipment for each stage. What's exciting about the research we're doing here at the University of Sherbrooke is that the technologies we're working on should lead to promising results at much lower costs," states Professor Bruna Rego De Vasconcelos.

And lower costs mean faster potential application and commercialization. And commercialization leads us closer to genuine solutions for phasing out fossil fuel usage.

Reduce steps to cut costs

Unlike the usual industrial practices, our teams aim to eliminate several steps in the process—specifically, hydrogen production—to still manage to produce quality green fuels. The equipment for scaling and hydrogen production is highly costly, and all must be carried out under very precise and controlled conditions.

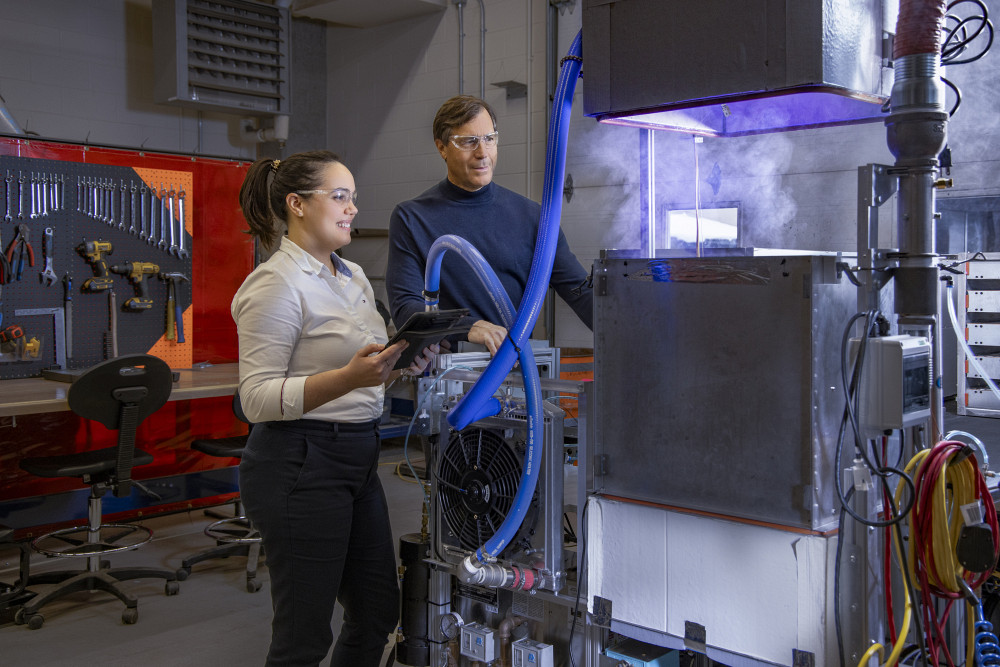

Professor Bruna Rego De Vasconcelos and Professor Martin Brouillette.

Pierre Pelletier, collaborator

By combining CO2, used here as a raw material, with water and electricity in a single step, we produce syngas, an intermediate gas subsequently used to produce the chosen type of green fuel based on our aims: methanol, methane, diesel, aviation fuel, etc. Optionally, we could even skip the CO2 concentration step, but, as Professor De Vasconcelos explains, there are advantages to retaining it:

"Exhaust gases—whether from industries or vehicles—usually contain CO2 levels quite low compared to other impurities, typically ranging from 10 to 15%. Capturing these emissions and adding a CO2 purification stage to increase CO2 purity to 80% significantly enhances subsequent efficiency. This is a major part of the research conducted by Professor Martin Brouillette's team, with whom I actively collaborate."

In our surroundings

There are many industries around us that would like to shift towards green and responsible energy consumption.

"For example, the maritime transport sector doesn't have many options to reduce its consumption of fossil fuels as an energy source. Methanol is becoming part of the equation and may eventually prove to be a good alternative for reducing these maritime emissions," indicates Professor Bruna Rego De Vasconcelos.

Clean Fuel Materials Challenge Program

About four years ago, the National Research Council of Canada (NRC) launched the Clean Fuel Materials Challenge Program, and Professor De Vasconcelos's team qualified right at its inception and has recently qualified again. The program aims to foster collaboration with leaders in post-secondary education and the industry to develop materials for technologies targeting the decarbonization of the oil and gas industry and the petrochemical sector in Canada.

"We have several partners involved in this project with the NRC. We are focusing on practical applications, and I love that. This project ultimately targets methanol as the fuel of choice. It's easy to store, easy to transport, widely used in the chemical industry and can also be used to produce other fuels," adds Professor Bruna Rego De Vasconcelos.

Among the project partners, note the participation of Sequoia, a company marketing biomass boilers and always searching for ways to optimize its processes. The University of Sherbrooke is also nearby, always on the lookout for new initiatives to become ever greener: with the exhaust from a generator, they plan to test the conversion to synthetic gas and then to methanol. Hydro-Sherbrooke is also a project collaborator, providing the necessary renewable electricity.

Additionally, beyond this CNRC project, it's worth noting the interest in the GENESIS project, led by Professor Jean-Michel Lavoie. Here, the technology is used at a more advanced technological stage, transitioning to a pilot scale.

"The GENESIS project team is already in collaboration with the City of Lac-Mégantic and its microgrid and aims to use our technology for three different processes. The first will be the gasification of forest biomass residues to produce syngas to power a generator. This generator then produces electricity, which is in turn used to power buildings. Additionally, both the heat emitted by the generator is captured to heat mobile greenhouses, and its exhaust gases are used to produce green diesel. It's a beautiful conversion cycle," reports Professor Bruna Rego De Vasconcelos.

It seems like it won't be long before large organizations will be able to capture their greenhouse gases to convert them into synthetic gas and directly fuel, for example, their vehicle fleets.