Scientists invent CO2-absorbing cement 🌎

Published by Cédric,

Article author: Cédric DEPOND

Source: Northwestern

Other Languages: FR, DE, ES, PT

Article author: Cédric DEPOND

Source: Northwestern

Other Languages: FR, DE, ES, PT

Follow us on Google News (click on ☆)

Concrete, the most widely used material in the world, is responsible for nearly 8% of global CO₂ emissions. A team from Northwestern University proposes an unprecedented solution: using electricity and seawater to create sand and gravel substitutes capable of permanently trapping carbon.

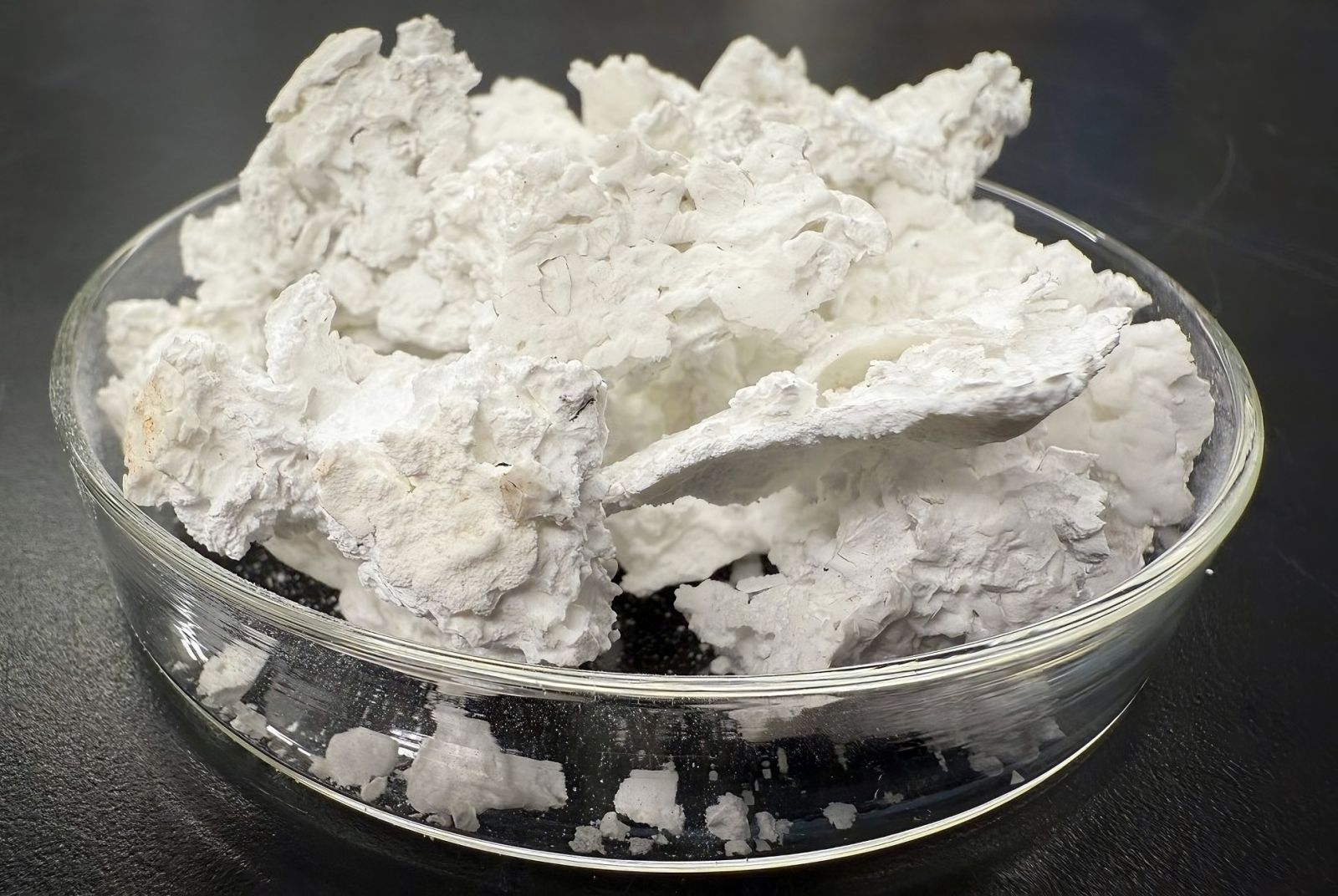

Researchers have created solid CO2-based materials that can be used in concrete as replacements for sand and/or gravel. They could also be used to manufacture cement, plaster, and paint – all essential finishes in the built environment.

Inspiration from the oceans

The process is inspired by the formation of seashells and coral reefs. By applying an electric current to seawater enriched with CO₂, scientists trigger the formation of solid minerals like calcium carbonate.

These chemical reactions accelerate a natural process that takes millennia in geology. Researchers can adjust the texture and density of the resulting materials by modifying the current intensity or the injected CO₂ flow rate.

According to research published in Advanced Sustainable Systems, these synthetic minerals store up to half their weight in CO₂. Their limestone-like composition makes them ideal candidates to replace sand in concrete.

Large-scale applications

In partnership with Cemex, scientists have demonstrated that these materials could also serve as a base for cement, coatings, or paints. Their production simultaneously generates hydrogen, a valuable clean energy source.

This approach avoids sand extraction, whose global demand threatens marine and river ecosystems. Modular reactors could be installed near coastal cement plants for industrial integration.

According to the team's calculations, one ton of this material would store over 500 kg (1,100 lbs) of CO₂. Unlike geological storage, this method gives captured carbon a second life as useful construction products.

Going further: How does CO₂ mineralization work?

This chemical process converts carbon dioxide into stable minerals. In seawater, calcium and magnesium ions react with dissolved CO₂ under the effect of an electric current.

The reaction mainly produces calcium carbonate, identical to that found in seashells. Unlike liquid capture solutions, these solids present no risk of leakage.

This technique differs from traditional concrete carbonation, which only traps 5 to 10% of the CO₂ emitted during its production. Here, the material becomes a carbon sink even before its use.