⚡ A Breakthrough for Low-Temperature Fuel Cells

Follow us on Google News (click on ☆)

Solid oxide fuel cells, often called SOFCs, generate power by directly converting chemical fuel, such as hydrogen, into an electric current. Their advantage lies in high efficiency and long lifespan, but they usually require extreme conditions of 700 to 800 °C (1292 to 1472 °F). These temperatures necessitate the use of special and expensive materials, making the technology less accessible for common applications.

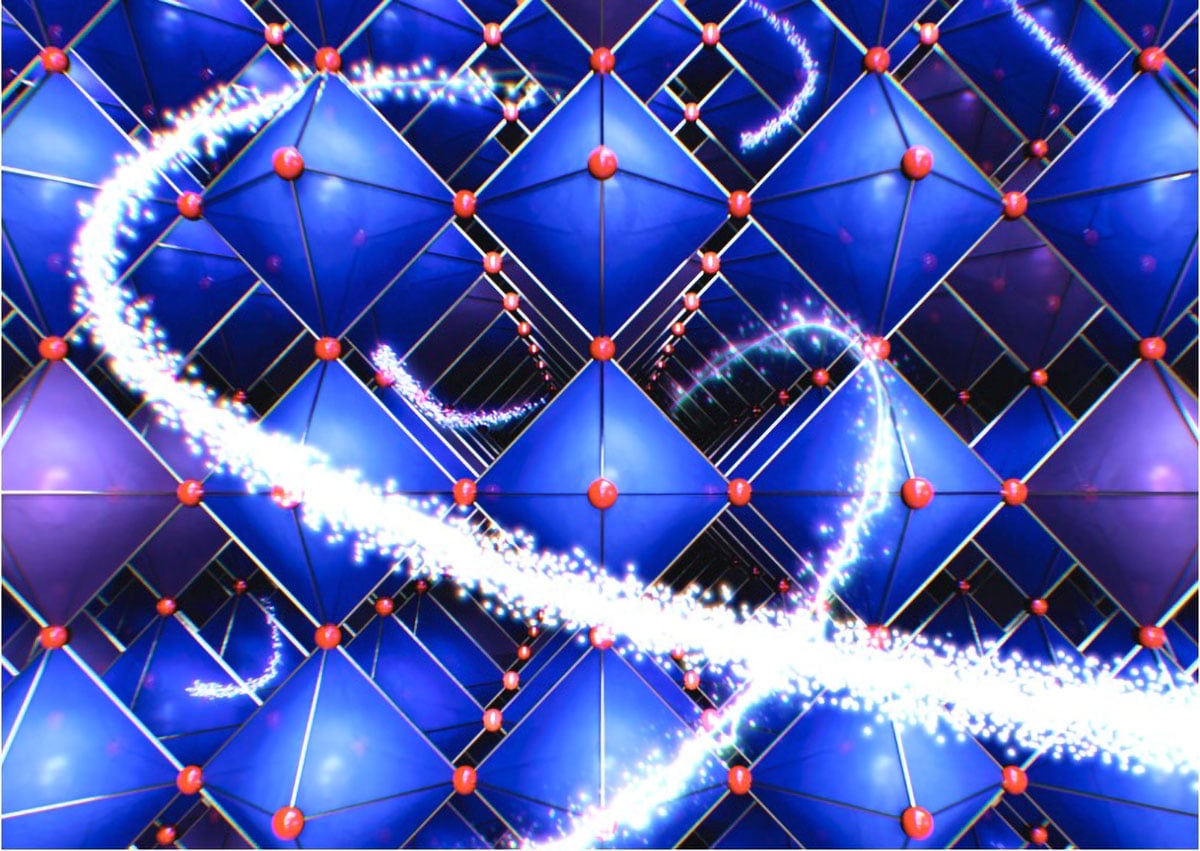

Digital image of the formation of proton transfer pathways in BaSnO3 and BaTiO3 due to high concentrations of scandium substitutions.

Credit: Kyushu University/Yoshihiro Yamazaki

A team from Kyushu University recently published a major discovery in Nature Materials: a SOFC capable of operating efficiently at just 300 °C (572 °F) instead of 700 °C (1292 °F). This dramatic temperature reduction is made possible by introducing scandium into compounds like barium stannate and barium titanate. The researchers measured a proton conductivity equivalent to that of traditional higher-temperature systems, paving the way for more economical designs. The underlying mechanism, detailed below, relies on the creation of specific pathways for protons.

Scandium, integrated at high concentration, modifies the crystal structure of the oxides to form networks dubbed "ScO6 highways." These paths provide a wide, low-resistance passage for protons, avoiding the usual blockages observed in heavily doped materials. This approach solves an old dilemma where increasing the number of mobile protons came at the expense of their speed of movement.

Operating at 300 °C (572 °F) instead of 700 °C (1292 °F) allows for a significant reduction in material and maintenance costs. The systems thus become more suitable for various domestic or industrial uses, without requiring ultra-heat-resistant components. This advancement also facilitates integration into existing infrastructure, accelerating the deployment of sustainable energy solutions.

The impacts of this innovation extend beyond fuel cells alone. It can be applied to low-temperature electrolyzers to produce hydrogen, to pumps for purifying it, or to reactors converting CO2 into valuable products. Thus, it multiplies the available tools for decarbonizing various economic sectors, strengthening the transition towards greener energy.

Proton Movement in Ceramic Materials

Protons are positively charged particles that move through fuel cell electrolytes to generate current. In ceramic materials, their trajectory depends closely on the arrangement of atoms in the crystal lattice. An ordered structure with appropriate spaces promotes rapid conduction, which is essential for efficient power production.

When elements like scandium are added, they modify the bonds between oxygen atoms, creating dedicated pathways for proton transport. These pathways, often compared to highways, reduce the energy barriers that protons must overcome to circulate. This allows for increased mobility even at moderate temperatures, where classical materials become inefficient.

The key lies in the balance between the number of available protons and the freedom of their movement. Too many impurities can clog the lattice and slow down conduction, whereas an optimal amount, as with scandium, optimizes both density and speed. This detailed understanding of atomic interactions opens the door to designing new high-performance materials.

Beyond Fuel Cells: Other Promising Applications

Scandium-doped oxides offering better proton conductivity opens up prospects for several technologies. In electrolyzers, for example, which produce hydrogen from water, this property allows the operating temperature to be lowered. This reduction leads to lower energy consumption and costs, making green hydrogen production more economically viable compared to classical processes.

Hydrogen pumps, used to separate and purify this gas, can also benefit from these materials. Efficient proton conduction at low temperature allows the design of more compact and less energy-hungry systems. This could broaden their use to industrial, even domestic environments, and thus contribute to the development of a more practical hydrogen infrastructure.

Another important field of application is the conversion of CO2 into useful products, such as synthetic fuels or chemical feedstocks. Reactors that use proton conduction are capable of catalyzing these reactions at moderate temperatures, which limits energy requirements and associated emissions. This method proposes to valorize CO2 instead of simply storing it, adding economic interest to efforts to limit climate change.

By touching on different fields, this innovation shows how a scientific advance can have positive repercussions across many industrial sectors.