Follow us on Google News (click on ☆)

These findings open up prospects in fields as diverse as aerospace and ballistic protection.

Boron carbide (B₄C) in ceramic form, meaning obtained through a high-temperature firing process, is well-known for its lightness, durability at extreme temperatures, and remarkable mechanical properties. It is a material of choice for applications in aerospace, cutting tools, and ballistic protection.

However, its large-scale industrialization is hindered by its hardness. Although significant, it does not exceed the threshold of super-hardness (the realm of diamond, cubic boron nitride, and other boron-based materials). Its low mechanical resistance to shocks is also problematic: under strong impact, it amorphizes (loses its crystalline structure), leading to a significant drop in its mechanical performance.

It has long been known that reducing grain size to the nanoscale (5 to 50 nm) improves mechanical properties. Indeed, reducing grain size increases the number of grain boundaries that hinder the propagation of dislocations that occur under mechanical stress. This results in an increase in the material's elasticity, a phenomenon known as the Hall-Petch effect.

Unfortunately, the boron carbide nanograins available until now were ten times too large to achieve such an effect. To optimize the mechanical properties of boron carbide-based ceramics, it was first necessary to synthesize these nanocrystals with sizes below 50 nm. It was then crucial to maintain their size during their assembly to form ceramics.

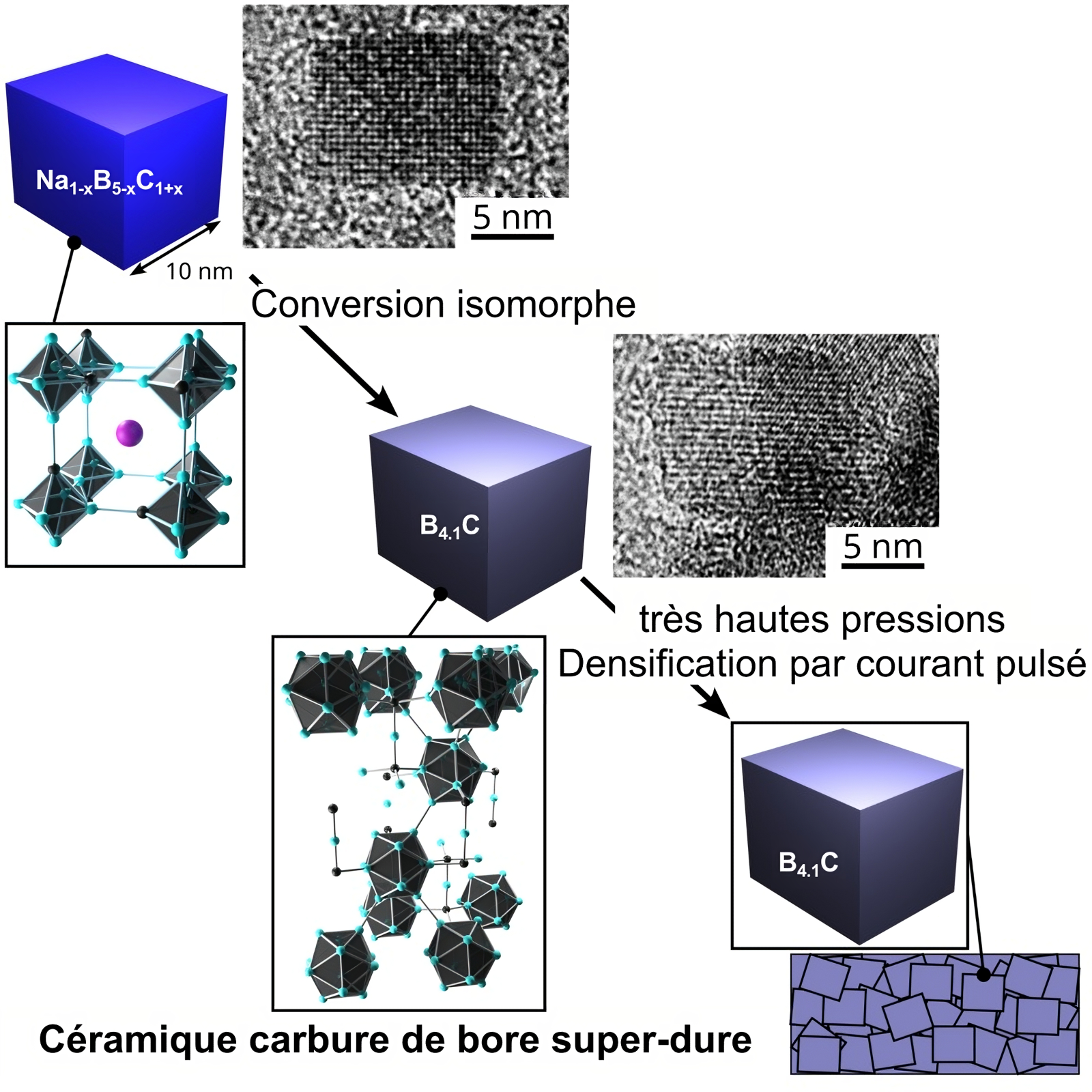

Boron carbide nanocrystals of controlled size designed by transforming sodium borocarbide nanocrystals. These nano-building blocks, densified under very high-pressure pulsed current, produce nanostructured boron carbide ceramics, a material with exceptional mechanical properties.

© David Portehault

A double challenge successfully addressed by a group of scientists from laboratories in Paris, Limoges, and Lyon.

By evaporating the sodium contained in sodium borocarbide nanocrystals at high temperatures, the scientists managed to convert them into boron carbide nanocrystals with a narrow size distribution centered at 10 nm. The densification of this boron carbide nanopowder to form the ceramic was then achieved using an original Spark Plasma Sintering (SPS) device under very high pressure, patented by the authors.

Coupling very high pressures (5 GPa, or approximately 725,000 psi) with ultra-rapid heating allows for rapid densification while limiting grain growth. The resulting nanostructured ceramics exhibit grain sizes below 20 nm. This specificity, which imposes a high number of grain boundaries within the structure, gives the material significantly increased hardness (exceeding the super-hardness threshold of 40 GPa, or around 5.8 million psi), as well as very high shock resistance.

This new super-hard nanostructured boron carbide described in the journal ACS Nano could find applications in fields where mechanical performance is critical, such as aerospace, cutting tools, ballistic protection, or nuclear industries.

Writer: CCdM

Reference:

Transforming Nanocrystals into Superhard Boron Carbide Nanostructures

ACS Nano 2024

https://pubs.acs.org/doi/10.1021/acsnano.4c08599